Your Cart is Empty

AUSTRALIA'S PREMIER BOXING EQUIPMENT & FIGHT SPORTS GEAR SHOP - FAST AUSTRALIA WIDE SHIPPING

AUSTRALIA'S PREMIER BOXING EQUIPMENT & FIGHT SPORTS GEAR SHOP - FAST AUSTRALIA WIDE SHIPPING

HOW A BOXING GLOVE IS MADE

In the perfect world you will have separate sparring gloves and bag work gloves, Your sparring gloves needs to have a softer outer foam to provide protection to you sparring partner and you bag gloves would have a higher density outer foam to make the glove more durable.

Hand made foam gloves have range of different qualities of foam that may be in gloves and the cost will vary, depending on which type of foam that is used.

Basic hand made layered foam gloves.

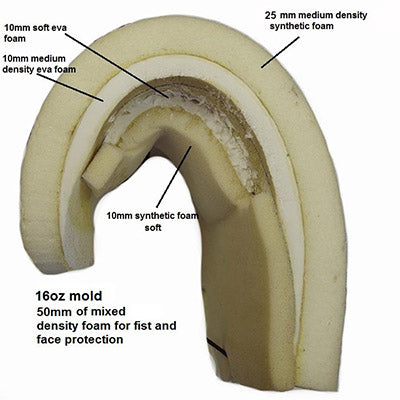

Below is a basic layered foam mould which is a standard for most gloves made in Pakistan.

This type of foams used above has two main reasons, one is cost and weight, the multi coloured compressed foams are one of the cheapest foams available and are heavy and make it easy to make a 12oz glove weigh 12oz without being too big.

The latex foam is a cheaper foam, it is also and is heavier than synthetic foams, which are better quality.

This sort of foam mould is from a training glove rather than a sparring glove as the outer foam is very thin and quite firm.

This foam mold below is the same sort of mold as above that has been use for a year or so, it has held up well, the black sponge foam has worn away and revealed the inner latex foam. The glove is still useable but should be replaced soon.

This kind of mold is basic cheap version of hand made foam, this style is found in 80% of the glove on the shelf at sports stores and most martial arts stores. It is quite good and durability is fair, they could last a couple of years with two nights a week training.

There are better quality molds available which are much more durable and comfortable.

High quality layered foam glove molds

The mold below is an example of a 4 layer higher quality hand made mould, the fourth layer is between the central eva and the inner layer.

The most important layer is the eva foam in the centre, which is a much more dense and durable than the other layers. It cannot be used as the outer layer as it is to dense to use a contact surface for the face.

This foam is from a 12oz Ringsport Rogue training glove and is 35mm thick, this glove is good for bag work, pads and partner work but not a a sparring glove as the outer foam is a bit thin for full contact sparring. The 14oz and 16oz model has a thicker outer layer for extra protection.

The mould below is a very high quality hand made foam mould ideal for bag work, pads and full contact sparring, this type of mould is found in high end gloves like Thailand made brands such as Top King, Twins and the Ringsport super pro range.

High quality examples of boxing gloves using the hand made quality foam above

Comments will be approved before showing up.

One of the best pairs of boxing gloves in the world is called the Super Pro Gel 2 gel boxing gloves. These are created and designed by us here at Ringsport. We used the finest selected materials with the latest boxing glove technology and features. We feel we have created not only the most comfortable boxing gloves ever, but also one of the safest. Learn all about the Super Pro Gel 2 boxing gloves in this article.